Paper Tube, Core & Canister Services

About Paper Tube, Core & Canister Services

Our company Colormann Pvt.Ltd. produces paper tubes (core), Kraft Paper, Kraft board (ply bond), and paper tube packaging, called Canisters. The use of cores in several growing industries has increased, including the manufacture of BOPP films, BOPP tapes, wound PP strapping, wound stretch films, food containers, postal tubes, and submersible paper tubes for packaging.

We have the largest foundation and our expert team is very professional. We have our own spacious factory and warehouse so that we can provide you with any range of product quantity.

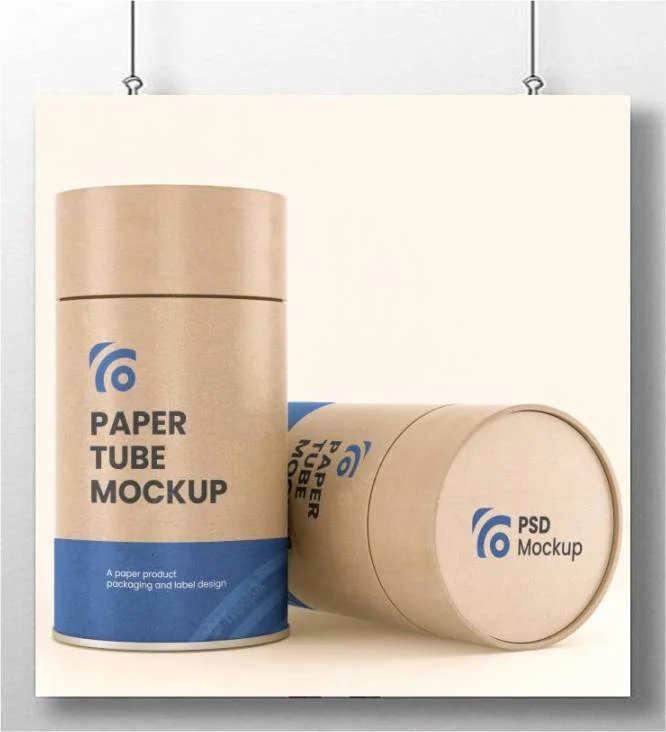

Paper tubes and paper cores are cylindrical-shaped products made from paperboard. They are used for winding and spooling various materials such as textiles, plastics, and films. Paper cores are also used in the manufacturing of different types of products such as adhesive tapes, aluminum foils, and labels. Paper tubes and cores can be custom made in various lengths, diameters, and thicknesses according to specific customer requirements.

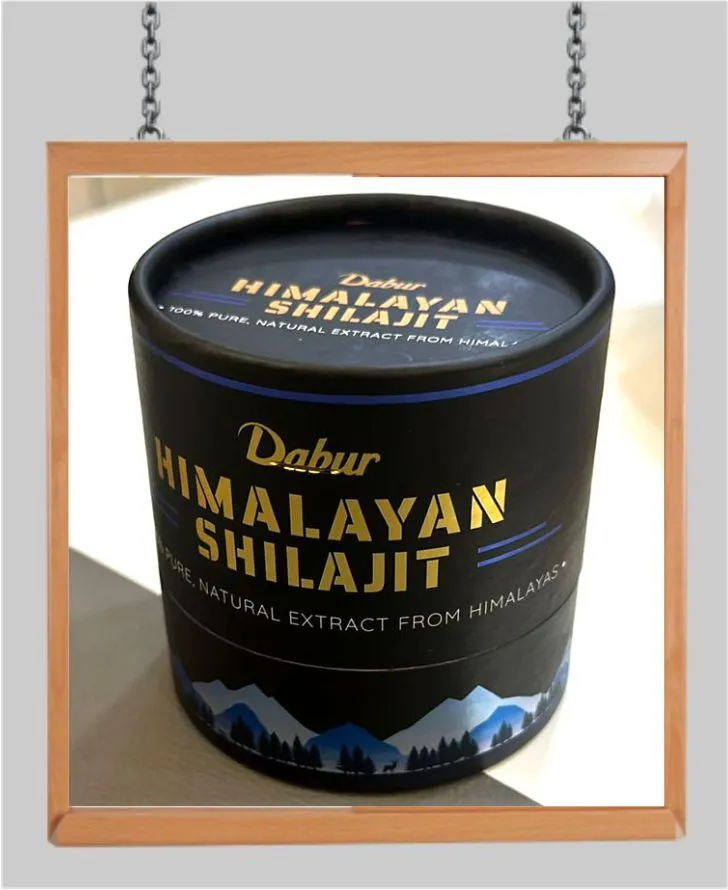

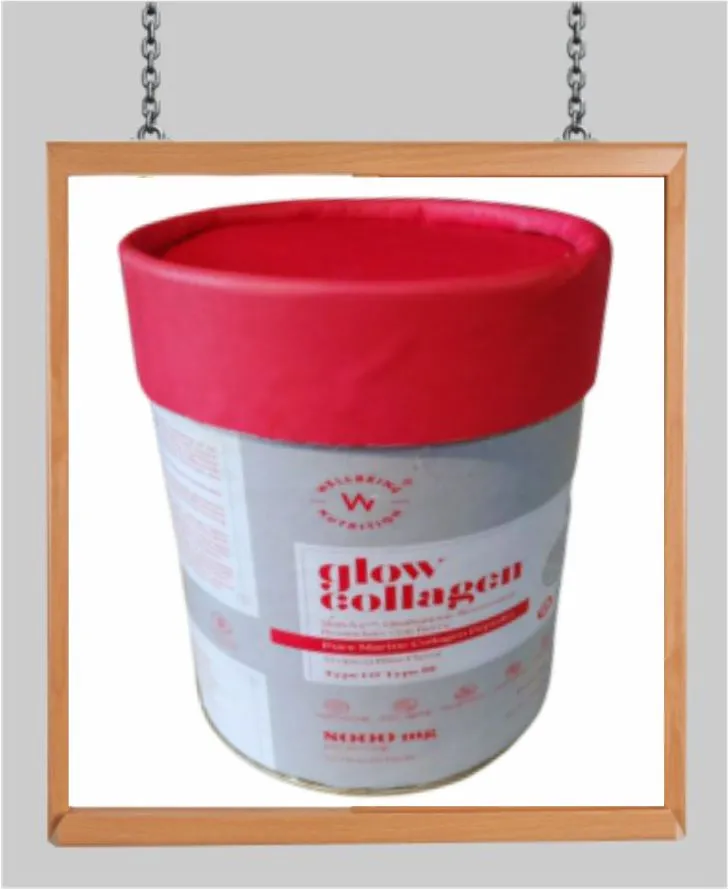

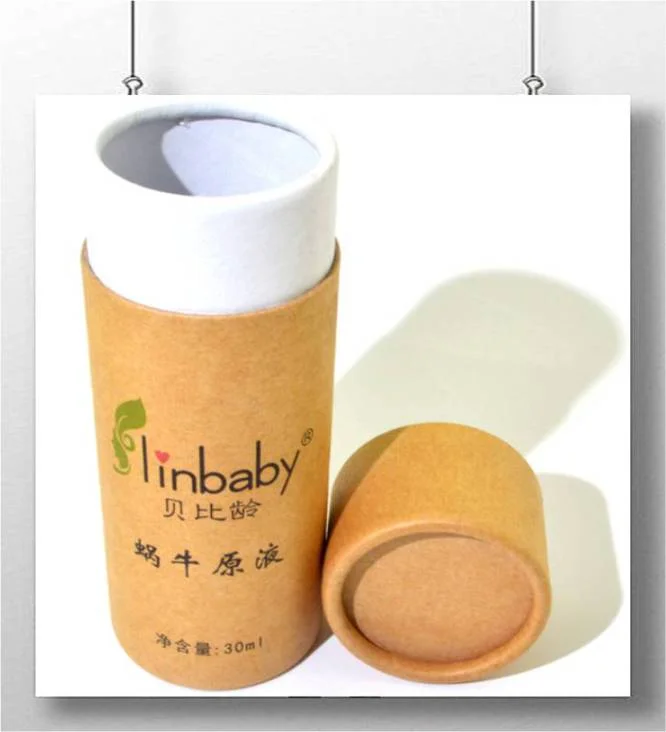

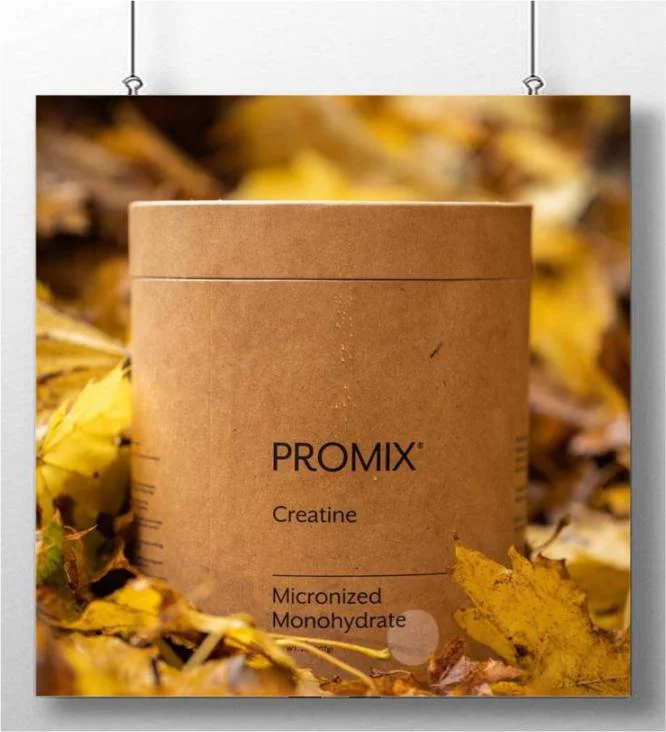

Canisters are cylindrical-shaped containers used for storing and packaging various products such as food items, chemicals, and pharmaceuticals. These products are made from high-quality paperboard and come in different shapes, sizes, and colors. Canisters can be customized with different types of closures such as metal lids, plastic caps, or snap-on covers. We can also be printed with customized branding and product information.

Colormann Paper Tube, Core & Canister Process

Paper tubes are made of paper or Kraft board sheet layers combined together to form strong, void, and usually cylindrical shapes. The thickness of the paper tube depends on the number of layers, as per our requirement. Here we offer all types of paper tube products such as paper cores, paperboard tubes, paper cans, fiber tubes, paper tubing, wound tubes, core board tubes, and cardboard tubes.

Paper tubes are made from large Kraft boards or paper sheets. First, we cut them into small thin pieces then attach those ribbons with a resinous sticky coating and wind them straight or at an angle around a mandrel configured into a specified shape. The larger part of the Kraft board is spirally bundled. At this time manufacturer can add multiple layers depending on the tube’s desired capacity. All tubes are measured according to their interior dimensions.

We also make waterproof and water-resistant cardboard for heavy-duty applications. In this process, the manufacturer uses additional resinous coating and interior waterproof sealing layers. Along with this, they make a mixture of resin, wood pulp, and adhesive, and then send it to an oven for additional curing. After this heat treatment, this product became harder, more durable, and adaptable to humidity and all forms of weather.

We use advanced machinery for the best-in-class product.

Offering a wide range of creative and novel designs of paper composite containers.

Textile tube large

Provide a large variety in size and colors of the textile tube at exciting rates.

Our Products Range

Our main motto is to provide the best quality product with the best service to our customers that fulfill their expectations. We have the largest foundation and our expert team is very professional. We have our own spacious factory and warehouse so that we can provide you with any range of product quantity.

Natural Duty / Going green / Environmental care

If you have any queries regarding our products, please let us know.

Quality Assurance

We are driven by a sincere group of merchants that help us ensure the quality of materials for our customers. Our shipping partners have been selected based on their market reputation, industry standards and customer feedback.

Additionally, our sellers guarantee that all the products are passed through various testing parameters using latest techniques and equipment by an experienced team of worth controllers to ensure that the commitment of delivering the best-in-class products to the customers is upheld.

Advantages of Paper Tubes

Cardboard is porous, and so in case of applications involving food processing or electrical wiring an additional protection of non-porous material may be needed to protect the tube from unwanted moisture or seepage.

Paper tubes are flexible, strong and because of their cylindrical shape can be used to pack items that may not be folded, such as maps, blueprints, posters etc., as well. Also, paper tubes are easily reused and recycled. Initially being recycled paper, using paper tubes not only supports sustainability twice over but are also cost-effective alternatives to materials like glass, plastic wood etc. Further, cardboard is easier to dispose of, compared to other materials, and has a better strength-to-weight ratio due to its durability and light weight. This makes heavy duty cardboard tubes less prone to denting or breakage, making it ideal choice for high priority shipping applications.